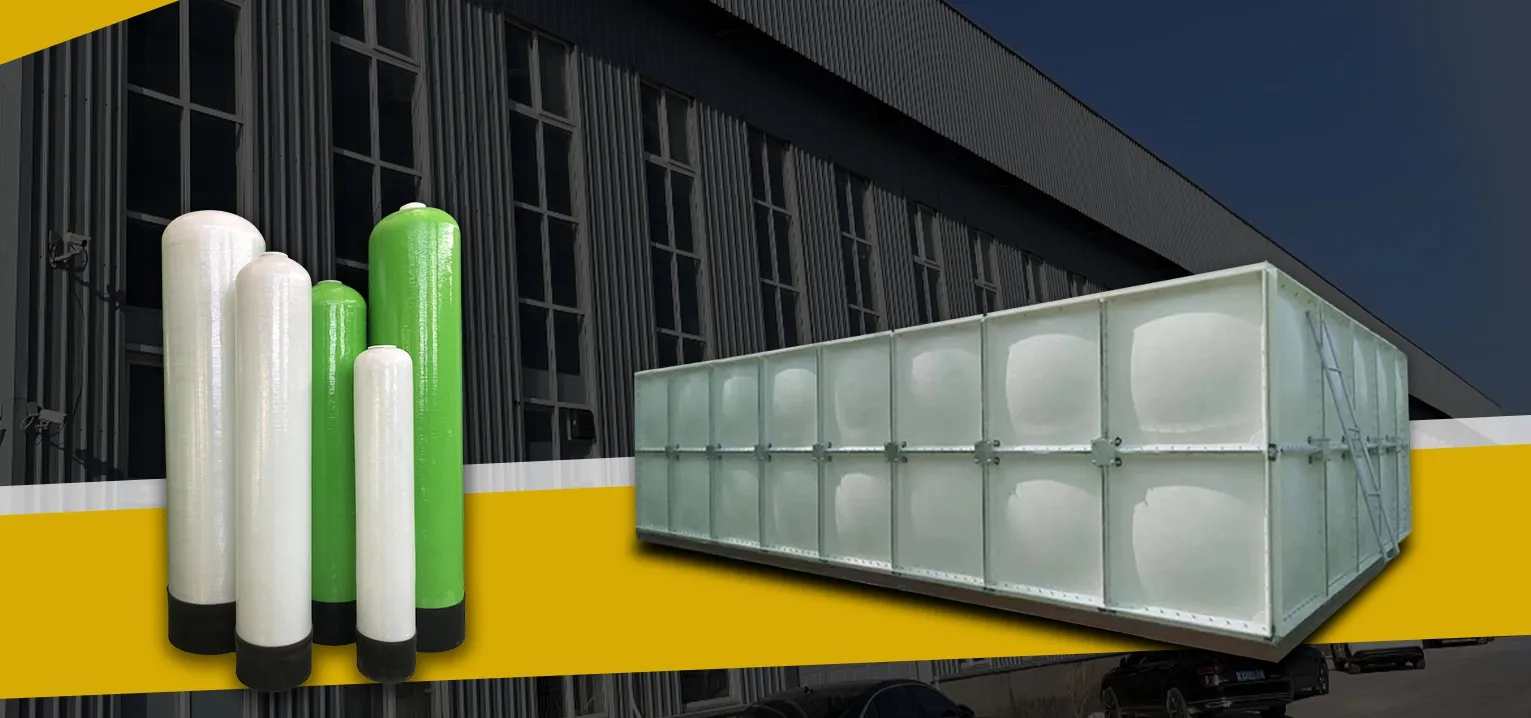

pressure tank

Links

Types of Sliding Door Wheels

cast iron wood burning stoves. Furthermore, the radiant heat produced by a cast iron stove is incredibly effective at warming up a room quickly and keeping it cozy for hours on end.

When we’re designing a custom iron fence or railing, we offer customers the option to add decorative elements made from cast iron to an otherwise wrought iron structure. Those pieces are then welded onto the pickets of the railing. This process can save on costs, since producing intricate decorative designs in wrought iron through hand forging can get expensive.

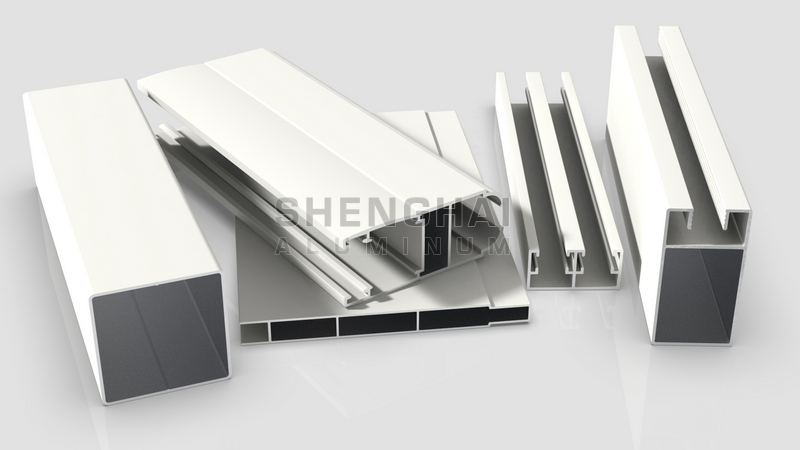

Thermal break profiles

“Dirt” posts follow their namesake and are the best option for bare ground. Before installation, dig a hole of approximately 12-18 inches with a diameter of 12 inches for each post in the fence. Then lower the fence post into position. Filling the hole with concrete permanently anchors the post to the ground.

7 Items to Consider When Buying Wrought Iron Fence and Gates

This process helps to strengthen the aluminum profiles for windows and doors. You can attain natural aging by exposing the profiles to room temperature.

Both types of iron are highly recyclable, which adds to their sustainability. At the end of their life cycle, iron fences can be melted down and reused, reducing the need for new raw materials and minimizing waste.

Follow the steps above and your wrought iron fence will see you through many years to come!

6. Lubricate the Rollers and Track Once you’ve successfully adjusted the rollers, apply a small amount of lubricant to the rollers and the track. This step is crucial as it reduces friction and ensures smoother operation over time.

Preheating Billet

Post caps are another place where cost cuts can be made. Lots of manufacturers will use a stamped steel standard cap which is easier to produce and squish on the top of the post. For the more decorative ball style post caps, some will make them out of aluminum, or worse, plastic. Our Stronghold Iron fence line uses cast iron caps for both styles that you can see in the photos below. The cast iron gives it a nice textured and authentic appearance.

These two types of fencing are made from different materials (obviously) and are also constructed differently.

The melted material is then poured into a mold (i.e. a “cast”) with a predetermined shape and allowed to cool. Cast iron structures can be as simple or intricate as the mold they were poured into, and the fact that the iron solidified all in one continuous piece helps make these structures extremely sturdy.

For instance, it features excellent corrosion resistance making it suitable for doors and windows applications. It is comparatively lightweight and exhibits incredible weldability, workability, and machinability.

It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them

It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them stainless steel gate lock box. The box comes with pre-drilled holes for easy installation, and the adjustable mounting brackets allow you to customize the height and angle to suit your specific needs.

stainless steel gate lock box. The box comes with pre-drilled holes for easy installation, and the adjustable mounting brackets allow you to customize the height and angle to suit your specific needs.

In conclusion, the advantages of using aluminium window extrusion profiles in construction are undeniable. From their durability and strength to energy efficiency and design versatility, these profiles provide a wide range of benefits for both residential and commercial buildings. As one of the leading aluminium extrusion suppliers in the industry, high-quality aluminium window extrusion profiles that exceed industry standards. If you are looking for reliable and aesthetically pleasing window solutions, consider incorporating aluminium window extrusion profiles into your next construction project.